WMS Process flow

Warehouse management includes core processes. Each process influences the efficiency, so every step must be optimized for the warehouse operation to run like a well-oiled machine:

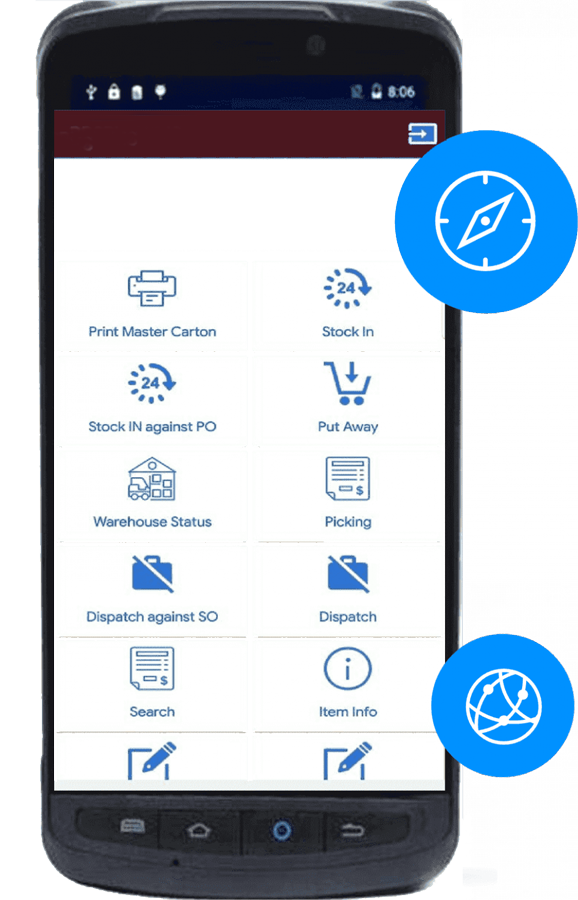

- Receiving. Check in and log incoming items. Verify that you’re receiving the right quantity, in the right condition, at the right time.

- Put-away. Move items from the receiving dock to their correct storage locations.

- Storage. Safely store and logically arrange inventory to enable fast and accurate picking.

- Picking. Collect the items needed to fulfill sales orders.

- Packing. Prepare the picked items for shipment. They must be safely packed into the correct packaging with an accurate packing slip.

- Shipping. Send out the finalized sales orders, ensuring that they are on the right vehicle, at the right time, with the correct documentation, so customers receive their orders on time.

Warehouse Optimization

Optimizing your warehouse operation involves fine-tuning each of these warehouse management processes. For example, when receiving goods, an organization can label items with mobile barcodes or attach RFID tags to make them easier to find when picking. During put-away, a well-managed warehouse operation stores items in the minimum amount of space to maximize the capacity of the warehouse. Other best practices for warehouse optimization include storing popular items in easily accessible areas and separating items that can easily be mistaken for one another.